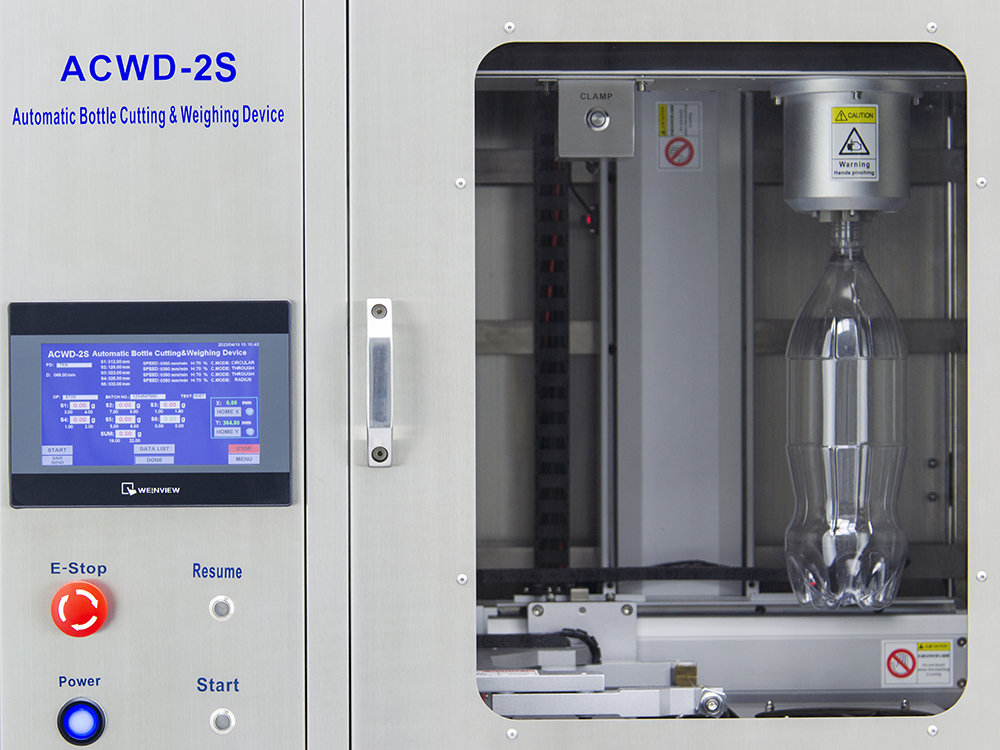

The AT2E ACWD-1 Automatic Bottle Cutting & Weighing Device offers an automated and cost saving way for cutting containers for section weight analysis. Automatic cutting and weighing, automated process controlling, ensures the cutting accuracy and repeatability, increases the analyzing accuracy, provides a better solution for bottle section weight analysis and more reliable data.

With ACWD-1, a PET bottle could be cut up to 6 predetermined sections and auto weighing to each section.

Features:

• Full automatic control, auto positioning for accurate cutting

• Automatic section cutting and weighing

•Able to perform circumferential cutting for deep dome bottles

• Data could be reviewed on screen or through software

• Motor control, hot wire cutting

Technical specifications:

• Sample range:

Height up to 360 mm Diameter 30 - 115 mm

• Power supply: AC 220V (AC 110V optional)

• Weighing range: 0 - 500 g

• Weighing resolution: 0.01 g

• Air supply: 5 - 8 bar

• Data interface: RS232

• Overall size: 700 (L) x 600 (W) x 1000 (H) mm

• Net weight: 80 kg

Optional model with auto sample conveying module ACWD-A:

Features:

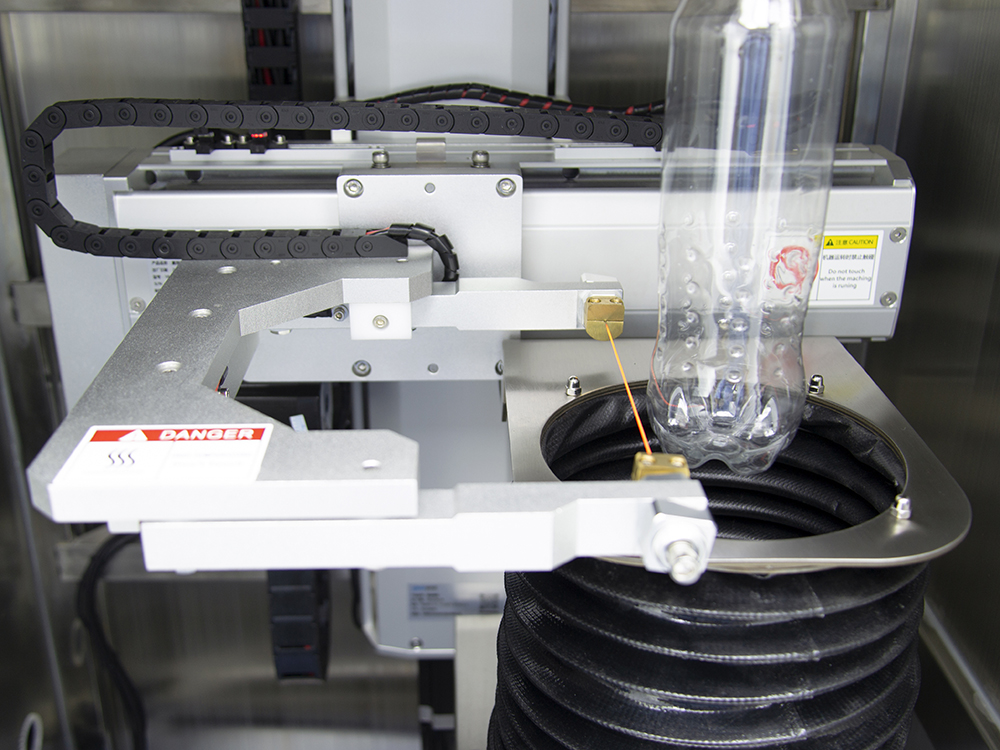

• Unattended operation process, cancels all the operators’ influence factors during the process, higher reproducibility

• PLC control, which ensures the measuring accuracy and repeatability

• Automated cutting process control, auto positioning the cutting point precisely

• Auto sample conveying, section cutting and weighing • Multiple cutting modes in option, compatible for various bottle types

• Sample conveying module is customizable according to the sample specifications and sample quantities

• High-speed motion module integrated, greatly reduced the inspection duration

• Configuration by password (administrator)

• Auto recording of measurement data during the test process (up to 990 groups of records), send out real-time data or send out records from data list.

• Measurement data can be recorded in system for reviewing or in the data acquisition software for data management

• Three different alarm alerts - buzzer, indication light and on-screen text alerts to notify the operator at the first place in case of any abnormal situation

简体中文

简体中文 English

English