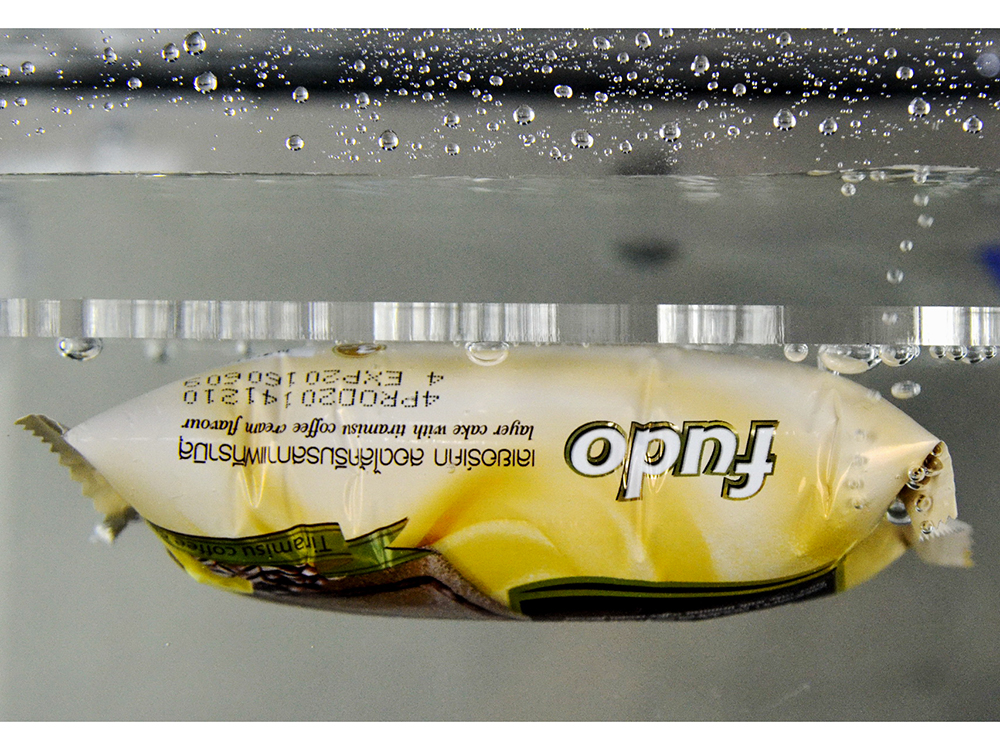

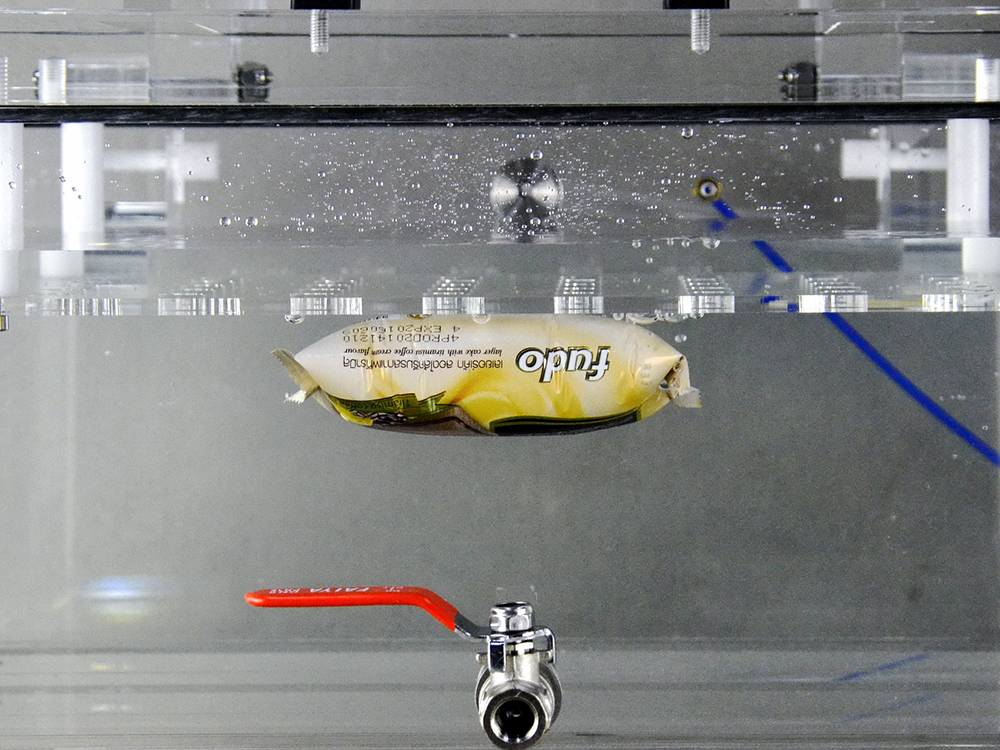

Leak detection by setting vacuum with or without step.

Tests on:

Bottles: Glass or PET and Preforms

Caps: Aluminium, other metal, plastic

Cans: Aluminium, others

Pots: caps, film, blisters etc.

Specifications:

Vacuum adjustable up to - 999 mb pressure up to 1 bar

Box with dimensions upon request

Box made of polished transparent PMMA (very rugged)

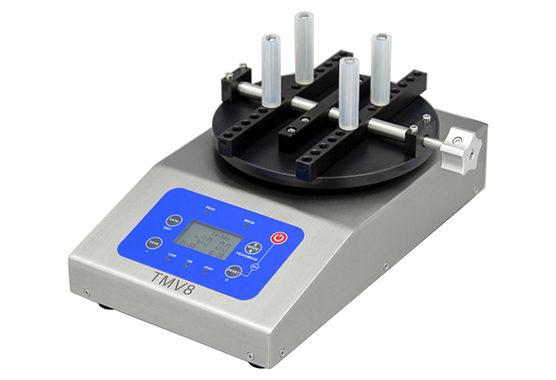

Easy to use and safe by touch screen PLC Control Panel

Dynamic display: Testing status / Date and time

Display: Product name / Operator / Lot No. / Sample No.

User defined test cycle (up to 16 modes). Pre-define up to 4 steps of each test. Vacuum level and holding time adjustable

For each step. Satisfies different kinds of testing request • Easy operation, only to select the pre-defined mode for starting a test no need to set the parameters every time

10 operators and 30 products memorisable

Lot No. and Sample No. editable

Review of the testing curve

RS 232 C output

Accuracy: 0.5% of the measure

Delivered with high performance vacuum pump

Runs with 6 bar network

Quick and easy verification and calibration

Immersion Cart

Mini-printe

简体中文

简体中文 English

English